Applications

MAXTOP: Your One-Stop Partner for Lubrication Reliability

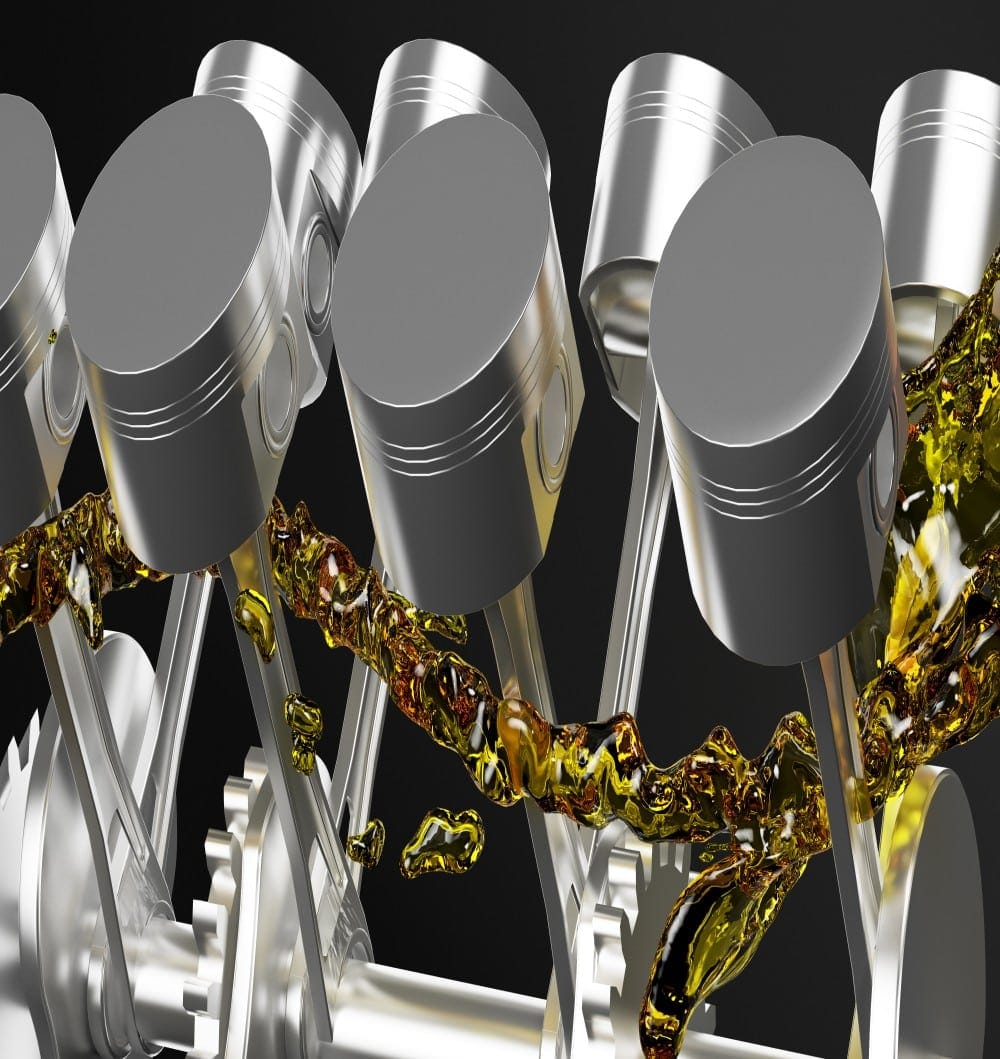

Customized Solutions for Equipment Protection

MAXTOP collaborates closely with clients to analyze specific equipment and lubrication requirements, designing tailored reliability programs that enhance operational efficiency and profitability. The process begins with an onsite equipment assessment conducted by local experts, who evaluate machinery conditions, environmental factors, and workflow challenges.

Comprehensive Lubrication Strategy

Data-Driven Recommendations

- Consultants deliver detailed reports covering:

- Optimal lubricant selection: Matched to equipment type, load cycles, and operational temperatures.

- Precision application methods: Including automated systems, grease volume control, and frequency adjustments.

- Maintenance schedules: Custom drain intervals and re-lubrication protocols to minimize downtime.

- Consultants deliver detailed reports covering:

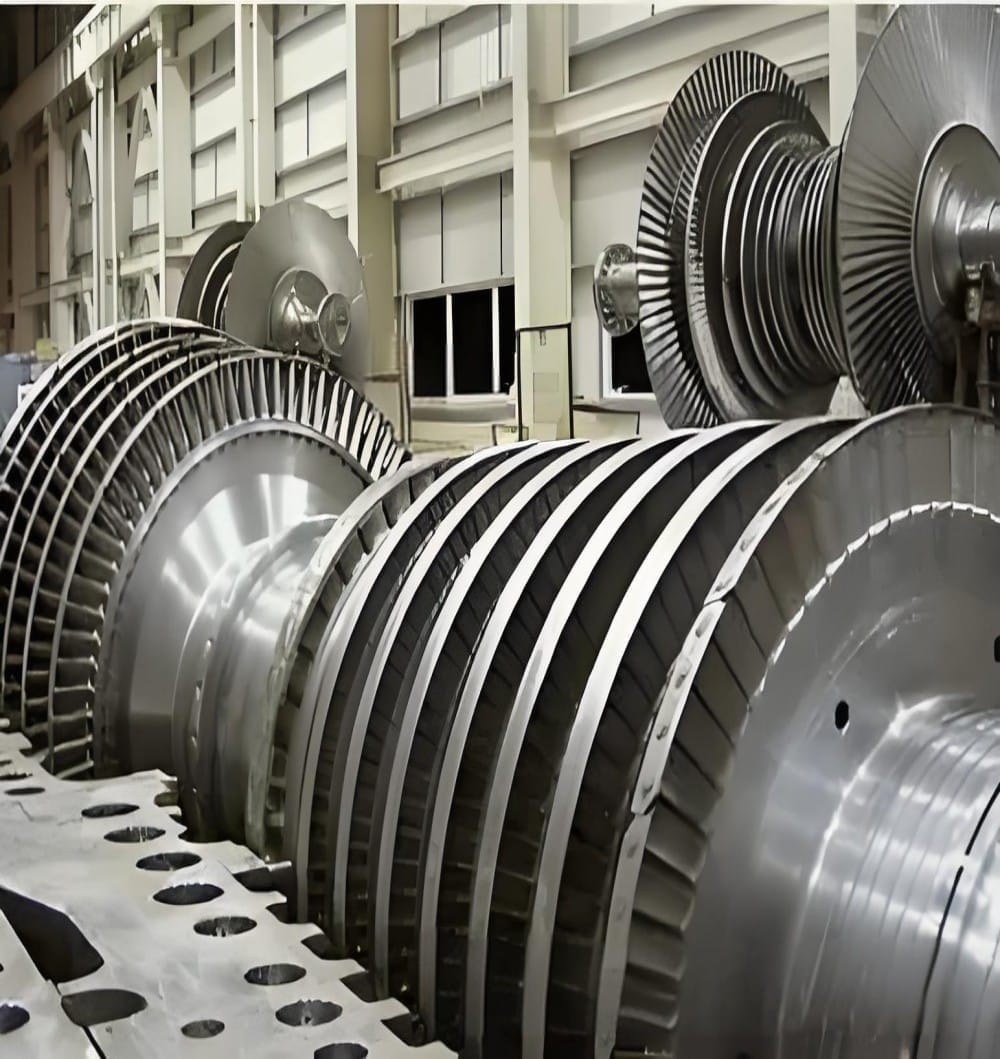

Beyond Lubricants: Holistic Support

- In addition to MAXTOP’s high-performance lubricants, consultants integrate solutions from reliability partners, such as:

- Smart monitoring tools for contamination control.

- Predictive maintenance technologies to preempt failures.

- In addition to MAXTOP’s high-performance lubricants, consultants integrate solutions from reliability partners, such as:

Driving Sustainable Performance

- Environmental stewardship: Programs prioritize reducing waste and optimizing resource use, aligning with global sustainability goals.

- Employee empowerment: Training initiatives ensure alignment with core values, fostering a culture of continuous improvement and collaborative problem-solving.

Global Expertise, Local Execution

- Proven ROI: Clients report extended equipment lifespans and reduced energy costs through optimized lubrication practices.

- 24/7 technical support: Leveraging a global network to address emergencies, from industrial pump failures to critical system overhauls.

MAXTOP: Engineering Reliability Through Partnership.

Key Differentiation

- Mission-driven approach: Combines technical precision with a commitment to societal and environmental impact.

- Adaptive solutions: Addresses both routine maintenance and high-stakes scenarios, such as emergency pump operations.